New Composite Material will Make Electric Cars More Efficient

One might think that science has peaked with the invention of electric cars but researchers are not done yet. Scientists at the Oak Ridge National Laboratory have found a new substance that can boost electricity transmission and is extremely lightweight. This new material can provide power-dense, ultra-efficient, electric vehicle traction motors.

According to the lead in charge Tolga Ayutug, ‘Such conductors can improve energy utilization through reduced ohmic losses, transport power with smaller size and/or lightweight wires/cables, and enable better thermal management across system components. Hence, the conductors potentially can result in immense technological and economic value in all energy sectors, ranging from on- and off-board components in electric cars, interconnects to electronic devices, and motors.’

Contents

The Project

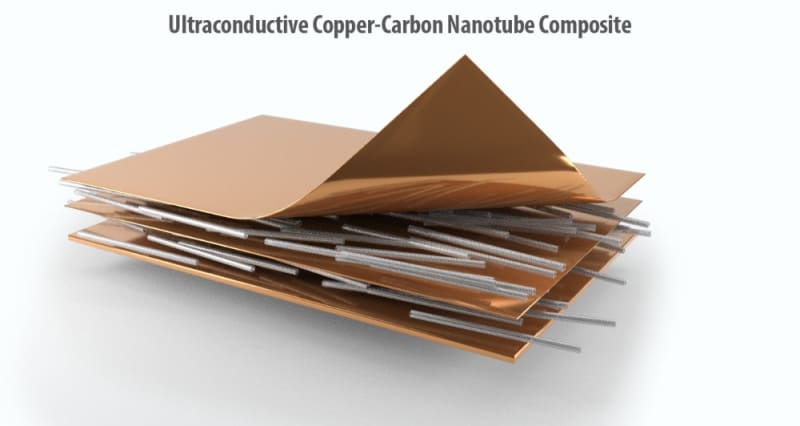

The researchers at the Oak Ridge National Laboratory have placed carbon nanotubes on flat copper substrates which resulted in a carbon matrix capable of better current transmission and better mechanical properties than copper.

The idea is not entirely new, however, many scientists before have tried to incorporate CNTs with other substances but they could not maintain sustainability and only short length materials were constructed. Some of them only micro and millimeters long while the longer versions were not able to offer the same performance output. The reason the team at ORNL were successful is that they deposited single-walled CNTs using electrospinning. Electrospinning is a process through which a jet of liquid is released through an electric field. As explained by Kai Li, a postdoctoral researcher in ORNL’s Chemical Sciences Division, ‘The technique provides control over the structure and orientation of deposited materials’. The method ultimately lets the researchers direct the jet of CNTs in one direction that led to the proper flow of electricity.

The next step involved the coating of thin layers of copper film on top of the CN with the help of magnetic sputtering and vacuum. These samples were then joined to form a highly conductive Cu-CNT network. This was done by forming a thick, uniform copper layer that was allowed to diffuse into the CNT matrix.

Tolga Aytug explained the process, ‘The basic approach to fabrication begins with formulating stable CNT dispersions for the deposition of uniform CNT coatings. Following CNT deposition in a manner that intentionally aligns the CNTs, samples were heat-treated to remove all organic chemicals from the CNT matrix. Subsequent deposition of thin copper over-layers by industry-standard physical vapor deposition and annealing processes enables high percolation conductivity throughout the entire CNT/metal matrix ensemble. The production of this material utilizes scalable and commercially viable processing methods, but the process is not as simple as melting copper and mixing CNTs together.’

The Final Product

Through this process, the scientist at ORNL was able to construct a copper-carbon nanotube composite 10 centimeters long and 4 centimeters wide, with outstanding properties. During analysis, researchers were able to find composite reached 14% greater current capacity, with up to 20% improved mechanical properties compared with pure copper, as detailed in ACS Applied Nano Materials

Tolga Aytug, the lead investigator for the project, said that “By embedding all the great properties of carbon nanotubes into a copper matrix, we are aiming for better mechanical strength, lighter weight and higher current capacity. Then you get a better conductor with less power loss, which in turn increases the efficiency and performance of the device. Improved performance, for instance, means we can reduce the volume and increase the power density in advanced motor systems.”

Inspiration

Tolga Auyg was asked about his inspiration regarding this latest substance developed, to which he answered, ‘Previous research on ultra-conductive metal composites (UCC) materials mostly involved mixing liquid copper with CNTs and extrusion to wire-forms, which mostly resulted in lack of controlled alignment of CNTs along the direction of the current flow; inhomogeneous distribution of CNTs on and into the metal matrix; and a poor fundamental understanding of Cu-CNT interactions affecting bulk electrical transport properties’ He added, ‘In our R&D activities, we were inspired by our previous research on the development of high temperature superconducting (HTS) wires where we have used tape geometries to produce these wires in wide width webs which were then slit into smaller widths to assemble them into HTS wires. We have mainly used thin-film approaches on a thin metal substrate/foil to create these HTS materials.’

Here we have followed similar approaches where we have deposited CNTs using commercially scalable, solution-based techniques on thin copper foils flowed by deposition of additional Cu thin films to produce a highly conductive sandwiched multilayer tape architecture. We have used CNTs because of their excellent electrical, thermal, and mechanical properties.’

Aim to reduce cost of electric cars

The main aims of the scientists who have invented this new material was to come up with a lightweight substance that could make any copper-bearing substance more efficient in the transmission of electrical current such as bus bars and traction inverters, smaller connectors for an electric car and wired charging systems. More importantly, they wanted to reduce the costs of electric cars and ensure more power efficiency.

According to the criteria of DOE’s Vehicle Technology’s Office for electric cars by 2025, scientists should come up with a source of increased power density and transmission in electric cars while reducing the volume of the motors 8 times. This can only be achieved by using a different sort of material that the vehicles are developed out of. This is where the newly invented material comes into play. Not to mention that this material can prove to be an alternative in all sorts of infrastructure that is made out of copper, such as all-electric conduction on and off-board the vehicle: in battery interconnects electric motor windings, bus bars, charging infrastructure and wiring.

The researchers of ORNL have always been conducting experiments on the superconductivity of substances which allows the transmission of electricity with minimal resistance. The lab’s superconductive wire technology has already been licensed to several industry suppliers, which is capable of providing high-capacity electric transmission with minor power losses.

Applications in other electric products

There are numerous applications that the company is looking forward to working on with the help of this new material. For example the possible use of double-wall CNTs and other deposition techniques such as ultrasonic spray coating working in coherence with a roll-to-roll system to produce samples of up to 1 meter in length. Aytug said,

‘While the new composite breakthrough has direct implications for electric motors, it also could improve electrification in applications where efficiency, mass, and size are a key metric. The improved performance characteristics, accomplished with commercially viable techniques, means new possibilities for designing advanced conductors for a broad range of electrical systems and industrial applications’

“Electric motors are basically a combination of metals — steel laminations and copper windings,” noted Burak Ozpineci, manager of the ORNL Electric Drive Technologies Program and leader of the Power Electronics and Electric Machinery group. “To meet DOE’s Vehicle Technologies Office’s 2025 electric vehicle targets and goals, we need to increase the power density of the electric drive and reduce the volume of motors by 8 times, and that means improving material properties.“