For the past several years, researchers have been searching for efficient renewable energy sources which could minimize any harmful or lethal drawbacks. Now, researchers in South Korea have successfully developed thin and flexible photovoltaic cells, or solar cells, which do not have any harmful effects on the environment.

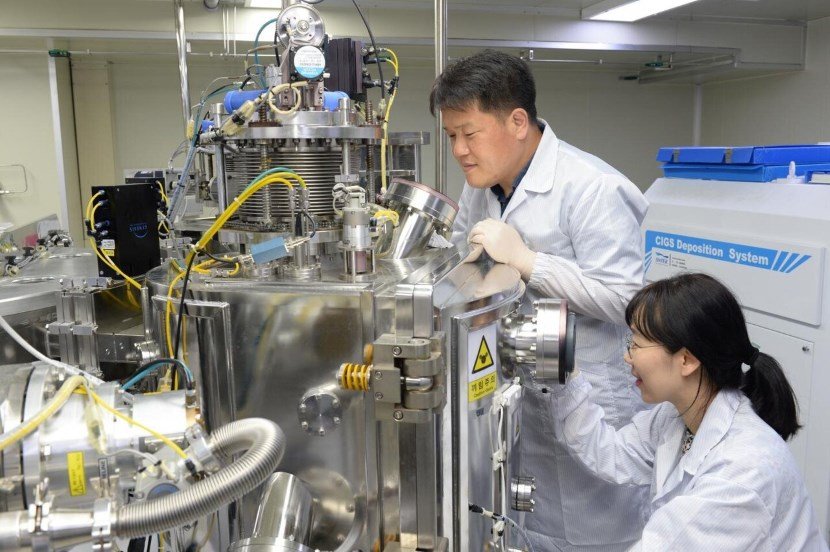

The Electronics and Telecommunications Research Institute (ETRI) developed eco-friendly colored copper indium gallium selenide, or Cu(In,Ga)Se2 (CIGS), thin-film solar cells. They are made by coating multiple thin films on a glass, plastic, or ceramic substrate, or on a flexible substrate.

Standard solar panels are thick and heavy, so installing them on rooftops or high platforms is an arduous task, and their rigidity also limits their uses. On the other hand, the CIGS solar cells are only 3µm in thickness and their flexibility broadens their applications and capabilities as a renewable energy source.

Contents

What makes these cells eco-friendly?

Cadmium is a heavy toxic metal found in most thin-film photovoltaic cells, making it difficult to promote their use. Now, ETRI has used zinc to solve this problem because it does not have any adverse environmental effects. They have replaced the cadmium sulfide present in the buffer layer, between the transparent conducting layer and the absorption layer, with zinc-based materials.

How efficient are these eco-friendly photovoltaic cells?

These solar cells have a relatively higher absorption coefficient among non-silicon based cells, resulting in high conversion efficiency and long stability. Where the standard commercial solar cells have a conversion efficiency of 15%, these cells have achieved a conversion efficiency of 18%.

How were these photovoltaic cells manufactured?

The CIGS solar cells were manufactured through chemical bath deposition method (CBD) using different thiourea (TU) mole concentration. CBD is a technique used to deposit buffer layers in thin film photovoltaic cells by immersing a substrate in a liquid solution.

According to the scientists at ETRI:

“The solar cells showed a substantial increment in the performance after light soaking treatment. The performance increment was found to be in proportion to the TU mole concentration used in zinc layer deposition.”

The ETRI researchers have described the cell in detail in ‘Ultrafast wavelength-dependent carrier dynamics related to metastable defects in Cu(In,Ga)Se2 solar cells with chemically deposited Zn(O,S) buffer layer’, which was published in Nano Energy back in August by scientists at ETRI; Woo-Jung Lee, Dae-Hyung Cho, Jung Min Bae, Myeong Eon Kim, Jaehun Park and Yong-Duck Chung.

How costly is the production of these photovoltaic cells?

CIGS solar cells require lesser raw material as compared to silicon-based cells, decreasing process and material costs. According to the International Renewable Energy Agency (IRENA), the general cost of solar power is expected to reduce to US$0.039/kWh (approx. TWD$1.17) in 2021, which is a 42% reduction as compared to 2019.

What colors do these eco-friendly solar cells come in?

These photovoltaic cells come in seven different slightly fluorescent colors, including pink, yellow, purple, green, and blue, without having to go through any additional process. These give them a remarkable appearance unlike the monotonous navy blue on standard solar cells, while cutting down on production costs.

ETRI also studies a mechanism for improving the conversion efficiency of solar cells with zinc-based buffer layer through photo-pumping terahertz spectroscopy. This particular study could provide a foundation for the next generation eco-friendly solar power.

As stated by ETRI chief researcher Yong-Duck Chung:

This technology will contribute to the solar power system development through the production of high value-added color photovoltaic modules.